|

This article is cited in 2 scientific papers (total in 2 papers)

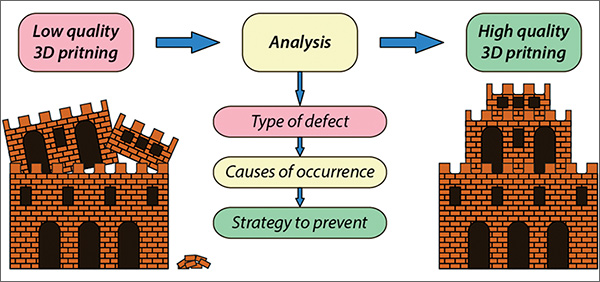

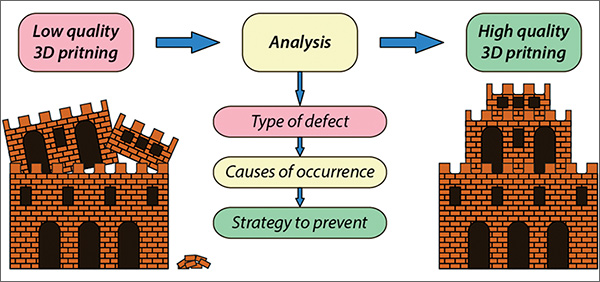

Analysis, classification and remediation of defects in material extrusion 3D printing

K. S. Erokhin, S. A. Naumov, V. P. Ananikov

N.D. Zelinsky Institute of Organic Chemistry, Russian Academy of Sciences, Moscow, Russian Federation

Abstract:

Additive manufacturing technologies (or 3D printing) have emerged as potent tools in the creation of a diverse array of objects, promising a paradigm shift in production methodologies across industries. In chemistry, it allows the manufacturing of reactors with complex topology. However, the benefits of these technologies can be diminished by the use of suboptimal parameters or inferior materials, leading to defects that significantly degrade the quality and functionality of the resulting products. An incomplete understanding of defect formation remains under the formulation of effective preventative strategies. In light of this, our review provides a comprehensive exploration of defects that arise during the Fused Filament Fabrication (FFF)—one of the most prevalent 3D printing methods. The defects are systematically classified according to several key characteristics, including size, type, mode of occurrence, and location. Each common defect is extensively discussed, detailing its external manifestation, root causes, the impact on the properties of printed parts, and potential preventative measures. Our findings unveil the complex interplay of material properties, printing parameters, and cooling dynamics in the defect formation process. This classification holds significant practical relevance, providing a solid foundation for the development of strategies for defect minimization and quality improvement in 3D printed products. It offers valuable insights for a broad audience, including researchers exploring chemical processes and additive manufacturing technologies, 3D printing engineers, 3D printer operators, and quality assurance (QA) engineers involved in production quality control. Furthermore, our review delineates the path for future research in this domain. There is a crucial need for the development of advanced machine learning and artificial intelligence models that can predict defect formation based on given printing parameters and material properties. Future investigations should also focus on the discovery of novel materials and refining of printing parameters to achieve superior quality of FFF 3D-printed products. This review serves as a cornerstone for these future advancements, promoting a deeper understanding of defect formation and prevention in additive manufacturing.

Bibliography — 180 references.

Keywords:

additive manufacturing, fused filament fabrication, defects, classification, quality, 3D printing, digital design.

Received: 14.09.2023

Citation:

K. S. Erokhin, S. A. Naumov, V. P. Ananikov, “Analysis, classification and remediation of defects in material extrusion 3D printing”, Usp. Khim., 92:11 (2023), RCR5103; Russian Chem. Reviews, 92:11 (2023), RCR5103

Linking options:

https://www.mathnet.ru/eng/rcr4447https://doi.org/10.59761/RCR5103

|

| Statistics & downloads: |

| Abstract page: | 54 | | References: | 2 |

|

Contact us:

Contact us: Terms of Use

Terms of Use

Registration to the website

Registration to the website Logotypes

Logotypes